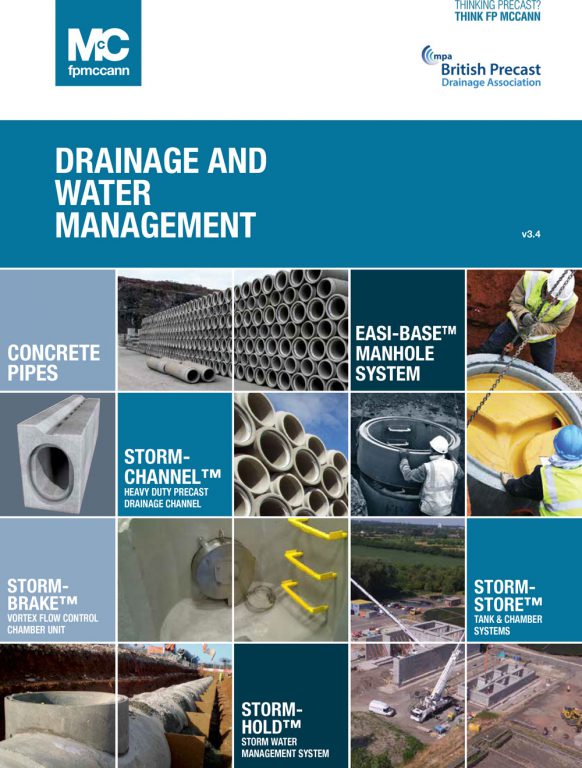

FP McCann is a leading manufacturer in the supply and delivery of precast concrete pipes that comply with accredited quality assurance schemes and meet the relevant British and European standards.

OUR PRECAST CONCRETE PIPE RANGE INCLUDES THE FOLLOWING:

- Spigot & Socket Pipes

- Precast Concrete Pipes

- Tumbling Junctions

- One Piece Integral Rubber Sealing System

- Anchor System

- A.T.O. Inflatable Pipe Stoppers

- Mechanical Concrete Pipe Lifter

8 Good Reasons why you should use concrete drainage

- Sustainability: Concrete drainage pipes outperform other types of pipeline solutions in a number of the environmental impact categories, such as human toxicity levels and chemical/hazardous waste generated.

- Strength: Concrete is much more durable than any other kind of pipe. Hence, it can carry more load at any given time and gains strength over time. It cannot be weakened by heat, moisture, mould or pests, nor will it rust.

- Quality: Since precast concrete pipes are produced in highly controlled plant environments under rigid production standards and testing specifications, they achieve consistent high-quality levels of performance. FP McCann’s concrete pipes are manufactured in accordance with BS EN 1916 and BS 5911 and certified by Quality Assessment under the Kitemark Scheme and ISO 9001.

- Whole Life Value: Due to its amazing structural properties and functional benefits, precast concrete pipes tend to attract lower insurance premiums than those built from other construction materials.

- Fire-Resistance: Being naturally fire-resistant, concrete forms a highly effective barrier to fire spread and it does not emit any toxic fumes when affected by the fire. It will not produce smoke or drip molten particles. Therefore, in the majority of applications, concrete can be described as virtually ‘fireproof’.

- Bedding Performance: The superior strength of concrete pipes enables recycles aggregate to be used as a bedding material, thus reducing costs and environmental impact during installation.

- Chemical Resistance: Concrete pipes and manholes are resistant to sulphate and chemical attack. Concrete pipeline products with higher design chemical classes of DC3 and DC4 are capable of withstanding attack from the vast majority of aggressive ground environments in the UK.

- Hydraulic Efficiency: The rigidity and mass of concrete pipes (both within the pipe and pipe joints) allows it to retain its shape over its long service life, preserving structural integrity and hydraulic efficiency, by minimising the resistance to water flow that often occurs when the shape or integrity of a flexible pipe is compromised through deformation.